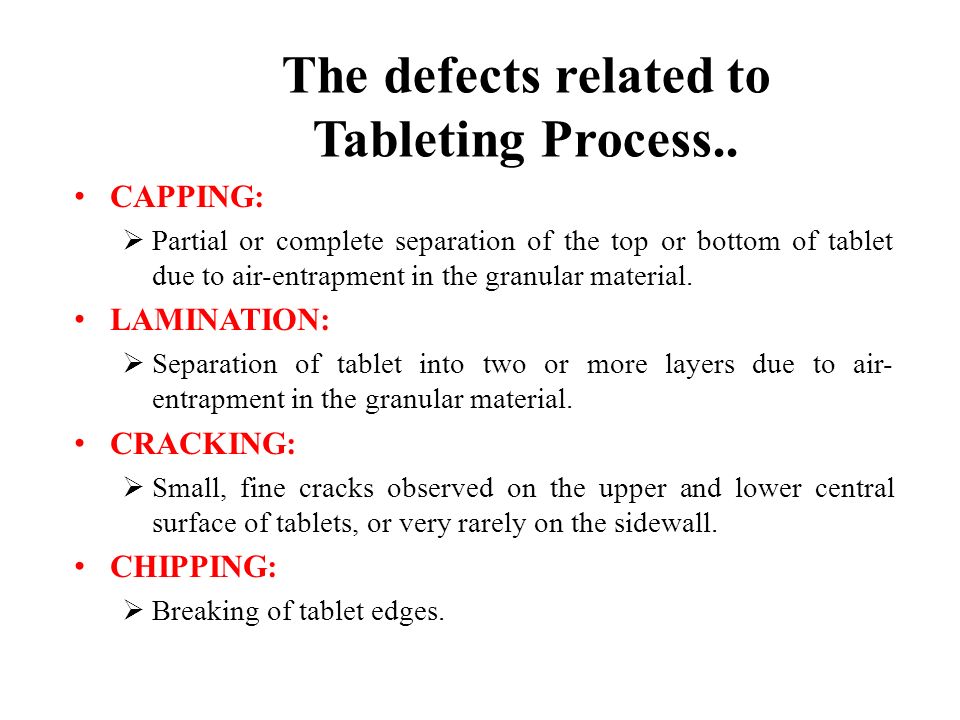

Abstract air entrapment efficiency of the powders is one of the main factors leading to occurrence of capping or lamination tendency of tablets manufactured from the directly compressible powder blends.

Tablet capping and lamination.

This challenge can be overcome by doing a pre compression as well as reducing the compression and minimizing the tableting rate.

Before rectifying be sure it is lamination where is the problem surface of tablet below the top layer or bottom of tablet.

Capping or lamination is an unsolved common problem in tablet manufacturing.

The following are some of the common factors which can cause tablet capping.

Machine related in this article we will be discussing five major causes of this problem and remedies for them.

First lamination is caused by air being trapped in the tablet especially among the granules or particles.

Better understand the tablet capping lamination phenomenon.

This is the problem faced in the formulation of the granules.

Using acetaminophen containing formulations we examined the potential use of a compaction simulator as a material sparing tool to predict capping occurrence under commercial.

Tablet capping and lamination powder compaction is widely used to produce pharmaceutical tablets and is referred to as a tabletting process.

Root causes of lamination.

Fines are small dust particles which.